Making Of A Bat

Making Of A Bat

Baseball Training Equipment is essential for player development, but sometimes we become so obsessed with any new fandangle “This is the Best” training tool … that we forget the basics in Baseball Training Equipment … The Bat.

Think about it for a second, the baseball bat is the single unique piece of equipment which produces All offensive attacks. You can’t steal first base or throw a home run, you must use the only offensive weapon available in order to create offense, and ultimately … runs.

Yet most people know very little about the process and history which constitutes the modern day baseball bat, but you’re about to change that and acquire knowledge 90% of avid baseball fans do NOT know.

Folklore has the Baseball Bat Making Process beginning in 1884, when John “Bud” Hillerich, son of the company’s founder, which originally produced various wood products .. Not baseball bats, was attending a baseball game being played by the Louisville Eclipse Baseball Team, and witnessed Pete Browning, “Old Gladiator” break his bat.

Seeing how upset Browning was, Bud invited him back to the wood company’s shop where Bud made a new bat, made of White Ash and gave it to him.

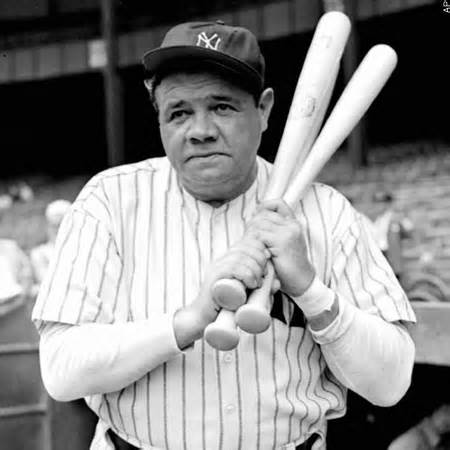

Making Of A Bat - Bambino

The next day Browning went 3 for 3 with the new bat, and with baseball players being notorious about following anything successful, they inundated the company with orders for baseball bats.

The company added making baseball bats to their line of products and named the bat the Louisville Slugg”er” which has been changed to Louieville Slugger.

Baseball players are amazingly superstitious and particular about their bats, as they are their key to successful hitting, but some may take it a little far. Frank Frisch, star player of the Giants and Cardinals, used to cure his bats by hanging them in a barn, during the off season, like sausages,

Ted Williams use to bathe his bats in alcohol in order to keep them cool while he was on a hitting streak, which was most of the time. It’s not clear why he did this, except in those early days patients in the hospital suffering a fever were often bathed with alcohol in an attempt to reduce the fever.

Williams & Babe Ruth were known to prowl the lumber yard, Williams searching for wood with narrow growth rings, while the Bambino preferred his bats to have pin knots in the barrels.

Making Of A Bat - Quality Timber

In order to understand the BaseBall Bat Making process we must first become familiar and understand the parts of the bat.

The Barrel is the most important part of the bat as it is here the ball is struck, and is the thickest part of the bat. Within this barrel is what’s known as the Sweet Spot,which is the exact spot best for hitting the ball.

In a wooden bat, the sweet spot is Small, but an aluminum or composite bat the sweet spot is quite large, which is why non-wood bats have become so popular, they are quite forgiving of a bad contact swing, which is also why they are banned in professional baseball.

The End of barrel is referred to as the end or top of the bat and is the same no matter the material. Moving down from the top is a tapered shaft known as the Handle, which is where the batter grips the bat. Metal bats may be covered with some sort of rubber in order to allow the batter to grip the bat, wood bats have no covering added.

The last piece of the bat is called the Knob,which is a round disc shape and prevents the batter’s hands from sliding off the end of the bat.

Raw Materials used in the Baseball bat making process.

Making Of A Bat - The Bat Maker

Historically, Ash trees, 40 to 50 years old, were the preferred wood for making bats due to its strength, flexibility and light weight. Trees from Pennsylvania and New York were sought because they tended to grow in dense clusters, where protected from wind, were forced to grow straight up towards the sunlight.

The reason a tree had to be 40 to 50 years of age was because it took that long for the tree to grow to a trunk diameter of 14 - 16 inches, from which 50 to 60 bats could be made from.

When harvested the trees are cut into 10’ through 16’ foot lengths and transported to the saw mill where they are carefully inspected for knots and uneven grain which disqualifies the wood from being used, which is normally about half of them. Once the log passes inspection the logs are sent to a hydraulic wedge, which splits them into what is known as 40” inch splits.

Each 40” split is then placed onto an automatic lathe which shaves the rough edges off of the wood, exposing the inside of the split, which is again carefully inspected for straightness of the grain. Insuring the grain quality, these 40” splits are now referred to Billets which indicates they’ve passed inspection and have been moved to the next manufacturing stage. The Billets are banded together in stacks, the ends sprayed with a preservative to prevent fraying and rotting, then sent to the bat maker.

The Billets are green wood meaning the wood still contains sap and gum, which must be removed in order to strengthen the wood and reduced breaking or splintering.

This is performed by a process called Seasoning, which is simply allowing the wood to air dry for a period of six months to two years depending on the wood.

Shaping and Sanding: Making Of A Bat

Once the billets have been certified as seasoned, weighed and inspected again for flaws, the process of shaping a baseball bat begins which is performed by skilled people called Bat Turners, who put the billets into automated lathes which shapes the wood into the form of a baseball bat, then are sanded smooth, inspected again then sorted according to weight.

Making Of A Bat - Waiting To Cure

MLB Orders:

Baseball bats ordered by MLB players must be made to specific requirements, therefore an exact model or template of the bat is maintained at the manufacturer. When a MLB team orders bats it may be something like:

* Six Bats - Johnny Bench

* Two Bats - Babe Ruth

The Bat Turners select a billet from the storage bins which fulfills the required weight and length of a specific desired bat. The billet is then placed in a lathe which communicates with a devise located above it holding the template bat.

The Bat Turner revolves the billet slowly on the lathe, shaving and sanding the bat into an exact replica of the template bat. This is a tedious project which requires the Turner to measure the billet every one to two inches, using calipers for accuracy, and weighing it repeatedly until the baseball bat is perfect.

Obviously this much attention to detail is not utilized in mass production bats, but quality control is still intense.

Making Of A Bat - Milling it Down

Branding, Varnishing and Staining:

The Baseball bat is branded with the Company trademark and the Player’s name associated with the bat, who it’s for. The Trademark is branded ¼ one quarter of a turn from the Sweet Spot of the barrel as an indicator of how the bat is to be held.

The bat is only stained, by dipping it into a vat of the desired color of stain, if ordered. All bats are varnished, then packed into cartons and shipped to the team or player.

Quality Control: - Making Of A Bat

Reputation for providing high quality bats are essential for a business to stay in operation, therefore quality control is taken quite seriously.

Some factories employ Compressed-Air Cannons, which shoot baseballs at precise predetermined spots on the bat, while others use robotic arms to hit the ball off of over-sized tees. High speed cameras record the impacts measuring an incredible amount of data, which is then analyzed by engineers and inspectors in order to insure bat quality.

Making Of A Bat - Almost Finished

There is the short version of how a baseball bat goes from being a tree in the forest to becoming a baseball bat in the hands of a MLB player or your kid playing ball in the backyard.

Modern day bats made of Maple wood are becoming more popular, but present problems, which traditional Hard Woods do not, but technology is quickly solving these issues.

Making of a Bat to Hitting Training Aids

New! Comments

Have your say about what you just read! Leave me a comment in the box below.